Sales Engineer: Grace Gao

Email: grace@rsnv.cn

WhatsApp: +86 199 2997 5286

RSNV-OP5000 comprehensive optical performance testing system for optoelectronic pods is primarily used for testing the overall parameters of optoelectronic pods. It is a high-precision, automated comprehensive testing platform for optoelectronic pods. The system integrates visible light, infrared, and laser multispectral testing capabilities, supporting multi-axis parallelism calibration, performance verification, and parameter calibration of the three core components of the pod (visible light, infrared thermal imaging, and laser ranging emission). It meets GJB/JB standard requirements and is suitable for large-scale comprehensive testing systems used in R&D verification, production assembly and adjustment, factory quality inspection, and equipment maintenance.

Function:

1.RSNV-OP5000 parallelism between the visible light axis, infrared light axis and laser ranging light axis of the photoelectric pod can be calibrated and adjusted.

2.RSNV-OP5000 deviation in parallelism among the visible light axis, infrared light axis and laser ranging light axis of the photoelectric pod can be measured.

3.RSNV-OP5000 laser intensity distribution, spot shape and divergence angle of the laser ranging module can be measured.

4.RSNV-OP5000 parameters such as MRTD, NETD, field of view, and distortion of the infrared camera can be tested.

5.RSNV-OP5000 parameters such as the field of view, distortion, MRC and resolution of the visible light camera can be tested.

RSNV-OP5000 Optoelectronic Pods Optical Performance Comprehensive Testing System

Component

Specification

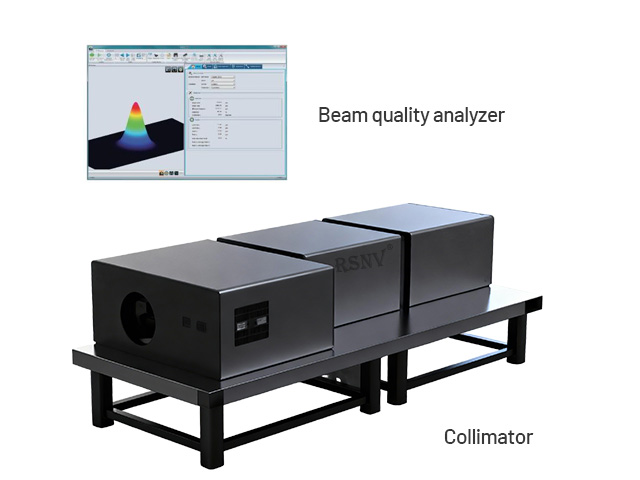

Collimator

Parameters

ZYP-5050L

Focal Length

5000mm

caliber

500mm

FOV

≥0.32°

Optical System Type

Off-axis Newtonian reflective

Coating

Metal aluminum film + protective film

Applicable Spectral Range

0.4-14μm

RMS better than1/15λ@632.8

50*50

100*100

0℃~125℃

-25℃~100℃

0.001℃

0.98±0.02

0.05℃

0.1℃

0.003℃/min

Temperature measurement accuracy (sensor):

±(0.06℃+0.005ItI)

15℃/min

10℃/min

Φ200

Φ50

≥99%

0-1000Lx

380-2500nm

PTFE / High-quality barium sulfate

Customizable

12

2048*2048

Pixel size 5.5μm * 5.5μm

1 inch

USB 3.0

905nm-1550nm

Sales Engineer: Grace Gao

Email: grace@rsnv.cn

WhatsApp: +86 199 2997 5286

Request A quick Quote(WhatsApp/wechat:+86-19929975286)